PVD ELECTROPLATING SERVICES

Physical Vapor Deposition

PVD nanotechnology has become an increasingly popular production solution because of its durable properties and eco-friendly application. It’s molecular-based installation also provides for the purest results. Our expert team relies on PVD nanotechnology to engineer the most sensitive products. If your new product design requires dependable, high-performance materials, PVD coating is an ideal solution.

What is PVD Coating?

Physical Vapor Deposition (PVD) nanotechnology is a manufacturing technique where solid metal is vaporized inside a high-powered vacuum. It is then bonded with electrically conductive materials. This gives your product additional physical properties, such as durability and conductibility.

Examples of PVD use fall into 2 categories: Functional and Decorative. Sometimes, it can be both.

Functional PVD

Functional coatings provide wear resistance and hardness to a product. Many drill bits and cutters are PVD coated in order to allow them to work on metals that are themselves hard (the bit or cutter needs to be harder than the metal it is trying to cut). Also, appliance components such as washer agitators, kitchen faucets, and shower suites are PVD coated to resist the scratching or marking that can occur when they come in contact with other metal components like utensils or steel wool.

Decorative PVD

Decorative applications consist of uses where you want a metallized component to match a very specific color. Common applications are found in automotive, major and small appliances, kitchen and bath plumbing and lighting. The colors are infinite and achieved through a combination of target metals, process gasses and time in the PVD chamber. Stainless Steel is the most popular PVD color and each OEM has its own version of Stainless Steel color.

Industries Popular for PVD Use

- Major Appliance

- Small Appliance

- Automotive

- Kitchen and Bath

- Industrial Tools

- Aerospace

- Many more

What are the Advantages of PVD?

Our PVD coating solutions offer you a competitive edge in three ways:

- Aesthetics: Metal coating, such as Stainless Steel, Black Chrome, Rose Gold, Polished Brass, and many more, will provide exotic metal finishes at a fraction of the cost.

- Performance: PVD coating solutions provide your product with an extra layer of protection against wear and corrosion. PVD coatings of titanium or chromium allows a coated plastic part to achieve extremely high levels of durability and hardness.

- Metal Finishing on Engineering Resins: Unlike Electroplating, which is limited to Nylons and alloys of ABS, PVD Nanocoating can be applied to nearly any engineering resin to combine the mechanical properties of engineering resins with the aesthetics of metals!

Why Choose CJT for PVD?

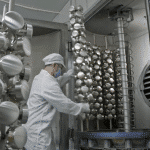

We have 20 years of experience with PVD and have a very close relationship with our PVD Machine manufacturer (VaporTech) in Colorado. This creates a partnership in achieving ways of accomplishing some of the more challenging finishes we are asked to do. The machines from VaporTech are specifically designed for plastic and the process is actually a subset of PVD called LTAVD (Low Temperature Arc Vapor Deposition). This allows us to PVD on plastic without deforming the part because plastic melts at elevated temperatures where metals do not.

Most of the PVD machines manufactured are designed for metal, not plastic. We are an ISO9001 certified organization, which includes our PVD operations. Note that we have no PVD capabilities in Thailand at the moment. One of our 3 machines in China will be transferred to Thailand by the end of 2022.

Our PVD Capabilities

By far, the most popular PVD finish is Stainless Steel. Each OEM has a slightly different interpretation of this finish, which is fine for us, because our machines have the capability to minutely adjust the brightness, color temperature and hue of any color target. Our PVD colors range from Cobalt Blue, to Bright Stainless, Black Chrome, Rose Gold and Polished Brass. Note that all of these colors are PVD on Chrome (i.e., we don’t plate gold, brass or cobalt!)

Fingerprint Resist: Our second most popular PVD finish isn’t actually a PVD finish at all, but an organic topcoat specifically formulated to resist fingerprinting on metallized finishes. This topcoat is applied over a PVD finish to allow users to maintain that beautiful finish with a minimum of maintenance.

PVD on Metal: Although our machines are designed specifically for plastics, they are also capable of applying a finish on metal components. In fact, after the chrome plating is applied to the part, the process used to apply PVD to metal is exactly the same as it is for plastic. In this case, because we use a low temperature process designed specifically for plastic, that same process will not damage metal. Unlike the reverse, where a PVD process designed for metal will most certainly be detrimental to plastic.

For more information about how we can use our services to positively impact your new development project, contact one of our team members at (847) 306-9877.